TYPICAL PROJECTS

We have completed hundreds of projects, big and small, since our inception in 2001.

While we enjoy a special focus on Dissolved Air Flotation and Filtration (DAF and DAFF), we deliver projects that draw from the full spectrum of water treatment technologies routinely used to make dirty water clean: for drinking, for irrigation, for discharge, or recycling.

With no two samples of water and no two sites being the same, no two treatment solutions can be the same. With that in mind, we pride ourselves on the truly bespoke and tailored approach that we take to solving water treatment challenges. Our gallery of projects below, and the breadth of our client base, testifies to the success of our approach.

Click on a category button to filter your search, and then click any of the thumbnails for more specific details and photos.

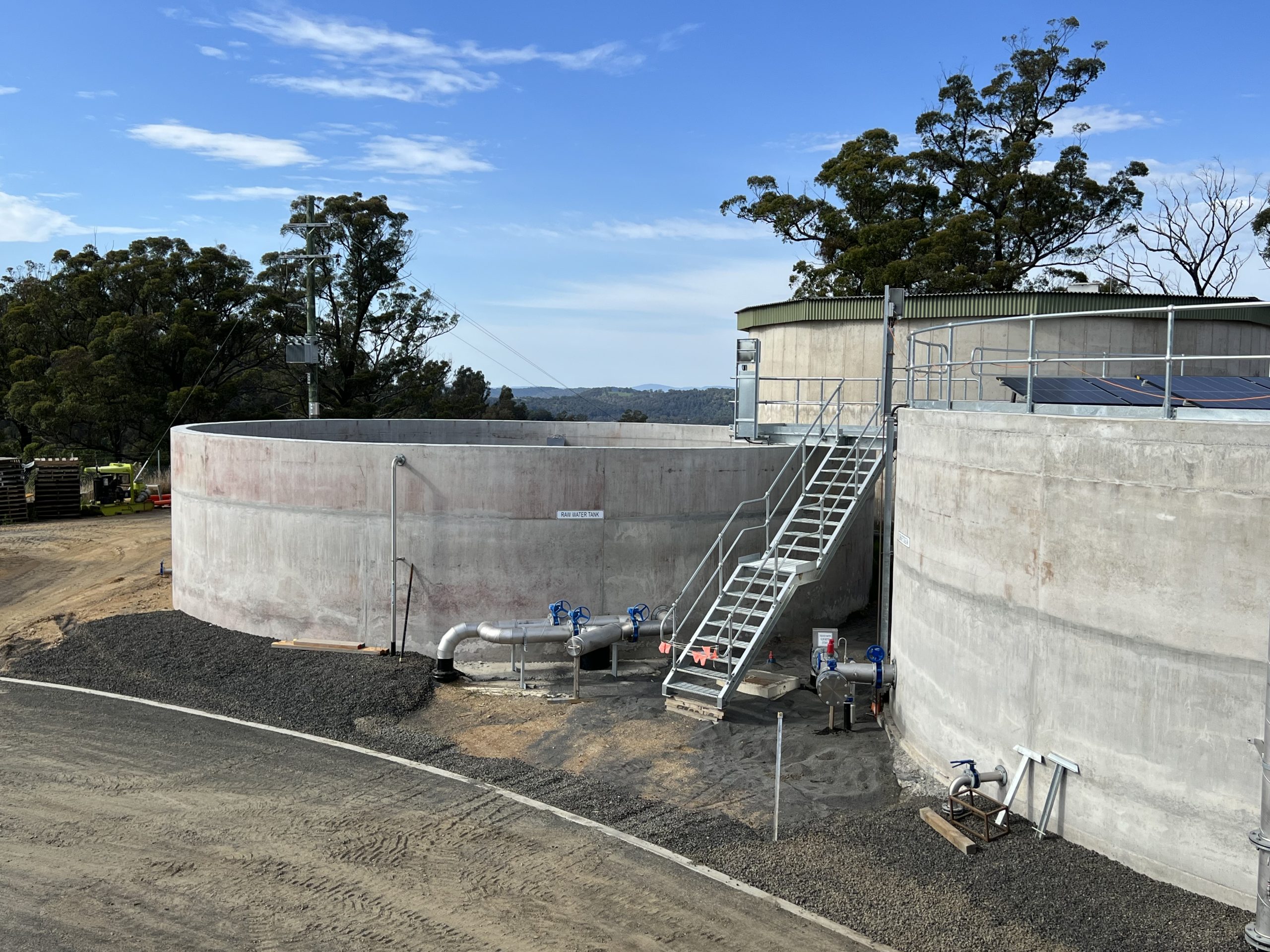

BROGO WTP

The Brogo WTP is a 3.5 MLD plant designed and constructed to treat moderate turbidity and colour contaminated water drawn from Brogo River, with historical water quality median figures of 0.5 NTU; 30 TC HU; 4.2 mg/L DOC. The project delivered:

- 3.5MLD bespoke designed Dissolved Air Flotation and Filtration (DAFF) Plant constructed of concrete cells.

- pH correction, coagulation and flocculation (including ACH and poly dosing), disinfection (UV + Gaseous Chlorine), fluoride dosing.

- Sludge Thickening, Sludge drying beds, Clear Water Storage.

- Innovations included:

- Chemical bunds sunken with grating at ground level for access without need for an stairs;

- Flexible dosing line within conduits;

- Optimised roof design and tank designs for solar installation.

- Challenges included:

- Overhead powerline running through the middle of the site initially created a lot of design constraints. It was decided early to proceed with powerline relocation approvals and design the plant while these approvals were being completed. This allowed better use of the area available and to remove an overhead hazard. Starting the approvals early meant that construction was able to commence and the relocation able to happen in the early stages with minimal impact on the construction program.

- Undersized transformer, which demanded working through approvals to upgrade, which were time consuming.

- Added Value included:

- Relocating power lines meant the building could be used to shield concrete tanks from view from the road, meaning these tanks did not need to be painted for aesthetic reasons, which was a saving for the client.

- Optimised solar installation.

Value: $8.4M

Back to PROJECTS GALLERY

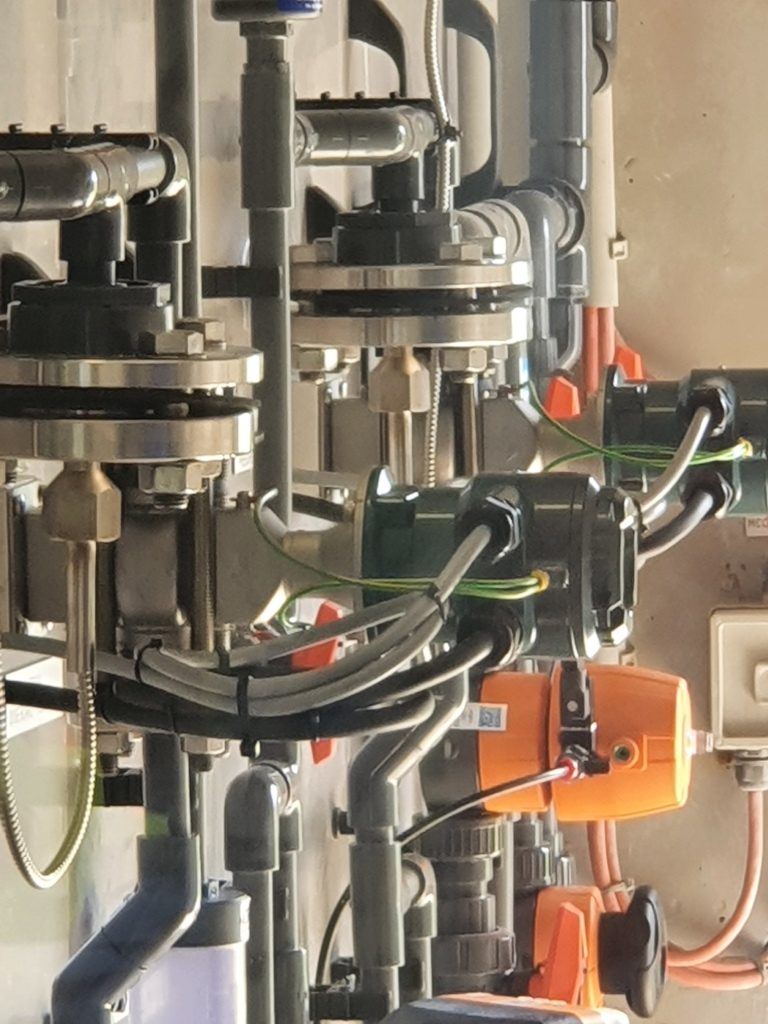

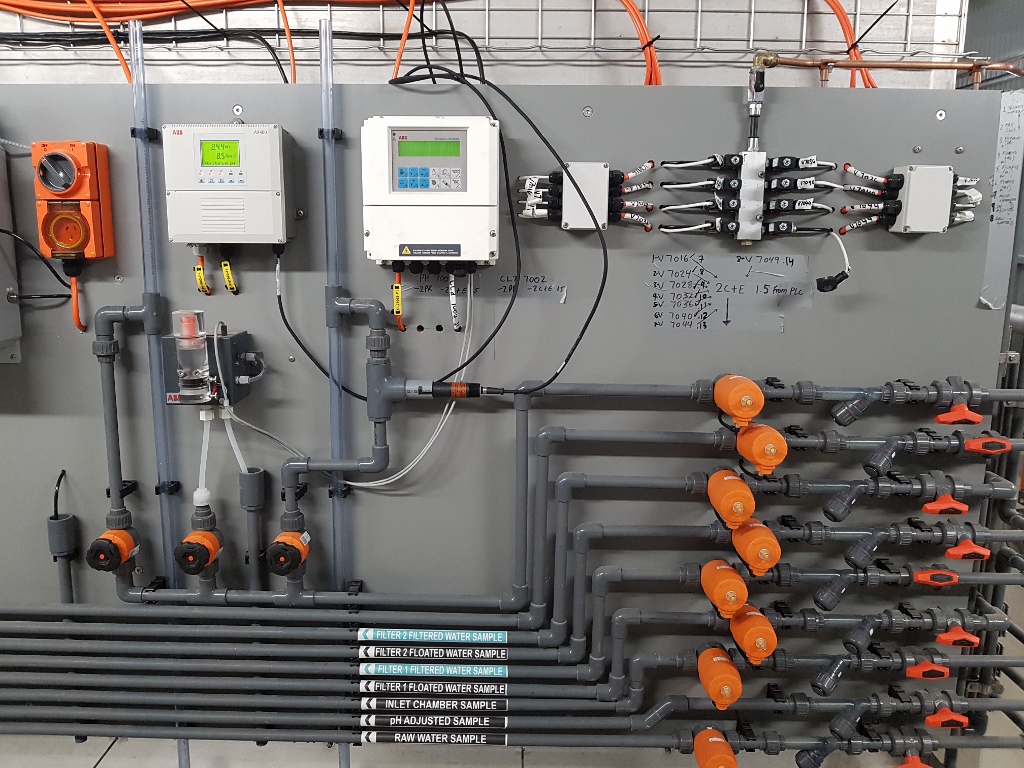

TERANG WTP FLUORIDE DOSING PLANT

LC Water won the Terang WTP Fluoride Dosing Plant project with Wannon Water in December 2022 to deliver a Sodium Fluoride powder storage, saturation and dosage system. The project required the delivery of the following scope.

- A Sodium fluoride storage and dosing equipment using a saturator system, including a saturator tank, stock tank, day tank, transfer pumps, duty/standby dosing pumps, water softener and all associated pipework and fittings.

- A Sodium Fluoride dosing control system complete with all electrical systems including control panel, PLC and HMI hardware, instrumentation, power supplies.

- A fluoride building Colourbond steel, with separate bunded and storage areas.

- 2 No. dosing lines providing duty/standby capacity, in a common buried sleeved pipe, delivering sodium fluoride solution to the dosing point, plus leak detection.

- Replacement of the above ground section of the existing DN200 treated water discharge.

- 2 No. Fluoride analysers; Sample pipework for the fluoride analysers

- A new service water system, including an offtake on the treated water discharge, duty/standby pumps, and all necessary pipework, power supply and controls to the fluoride building; New safety shower/eyewash and a hose down point.

Value: $764K

Back to PROJECTS GALLERY

DROUIN WASTEWATER TREATMENT PLANT

LC Water was subcontracted to support the Joint Venture head contractor ICON/CCB Envico to deliver the following:

- Mechanical installation of all free issued process equipment for this 12MLD sewage treatment plant, including MBBR systems, blowers, diffused aeration grids, screw presses and band screens.

- Procurement and installation of all pipework, chemical dosing systems, storage tanks, mixers and pumps

- Commissioning of the WWTP: Dry and wet commissioning, bioreactor seeding and membrane bioreactor testing and commissioning

- Project mechanical and process documentation, including the Operating and Maintenance Manual, Equipment schedules and data sheets, commissioning reports and mechanical/process drawings.

- Proof of Performance Testing, operator training and ongoing process/mechanical support

Value: $6.5 M

Back to PROJECTS GALLERY

LILYDALE STP – FILTER REFURBISHMENT

Lilydale STP Sand Filter Refurbishment

In April 2018, filter cell 1 was rendered inoperable by a rupture of the floor structure, likely due to a build-up of pressure caused by blockages in the pipework lattice and underfloor structure. Filter cells 2, 3 and 4 were also displaying symptoms of similar blockage.

With high pressure and high-level alarms becoming more frequent, and significant amounts of backwash flow being diverted through the pressure relief pipework, the cells were in urgent need of refurbishment.

LC Water and G&M Plumbing completed these works to schedule within six weeks of contract award.

- tightening/replacement of filter trough fittings to ensure structural integrity

- inspection and flushing of underfloor pipework and removal of sediment causing blockages

- replacement of nozzles

- installation of new gravel, sand and coal media (to be procured by YVW)

- air scour pattern testing and washing of new media

- recommissioning of the filter cells and handover to YVW operators

- review of filter cell operation and submission of recommendations

Value: $160K

Back to PROJECTS GALLERY

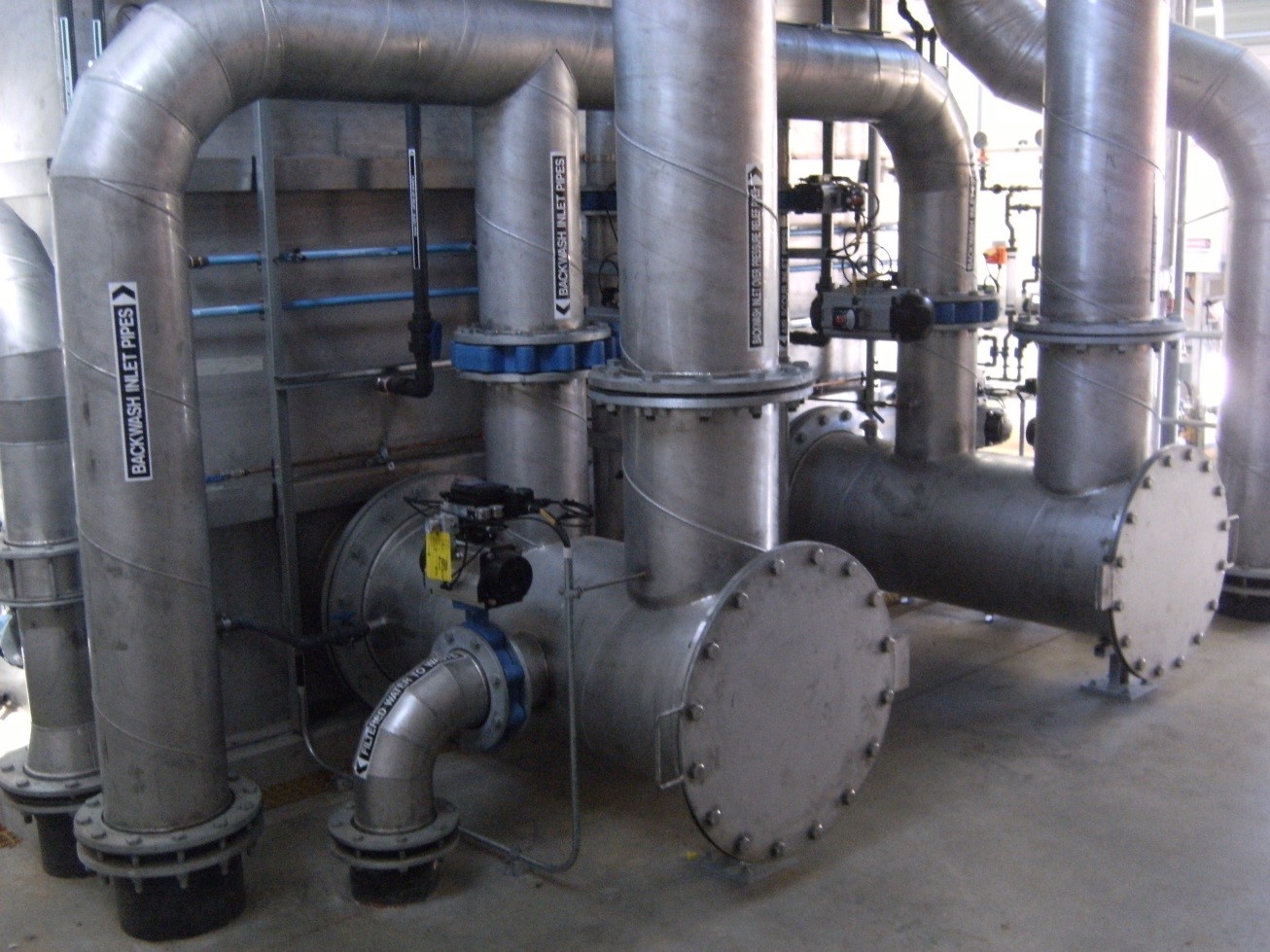

Eildon Wastewater Management Facility Tertiary Upgrade

The scope of this contract comprised the detailed design, supply, construction/Installation, testing and commissioning of a DAFF (Dissolved Air Floatation and Filtration) unit at the Eildon Waste Management Facility to replace the existing DAF (Dissolved Air Floatation) unit including all associated works as shown on the functional design drawings and described in the report and specification. The existing DAF unit was decommissioned and the redundant works removed as part of this contract.

One particular challenge overcome on this project pertained to the geotechnical conditions on which the plant was to be situated. Boring analysis indicated that the earth was particularly wet and not fit to support the slab foundations. Screw piling was thus implemented into the slab’s design to provide the necessary foundational integrity.

An overview of the scope is as follows:

- Supply new DAFF unit along with flocculation tank, static mixers and various other ancillary equipment described elsewhere.

- Site new DAFF unit on a concrete slab and house it under a metal carport with 1m skirting. Only steps / Stairs are acceptable on DAFF Unit. Ladders will not be acceptable. Skirting and gutter requirements as per the Building code of Australia. Lighting for the DAFF unit to be mounted on Walls for easy access and maintenance.

- The DAFF package shall include a standalone PLC based control system to enable the filters, pipework and valves to be assembled, factory tested and delivered as a working and functional unit. DAFF unit with a glass viewing panel will be preferable.

- DAFF package to include Recycle pumps, Air Blowers, Air compressors along with all piping and valves.

- The DAFF system also includes Backwash Pumps along with pipework and valves.

- Provide new cabling from existing switchboard to DAFF switchboard.

- Upgrade existing switchboard in control building as described in technical specifications

- Decommissioning and demolition of existing flocculation tank, DAF unit, back wash pumps and all other redundant units and associated pipework and cabling.

Value: $1.1M

Back to PROJECTS GALLERY

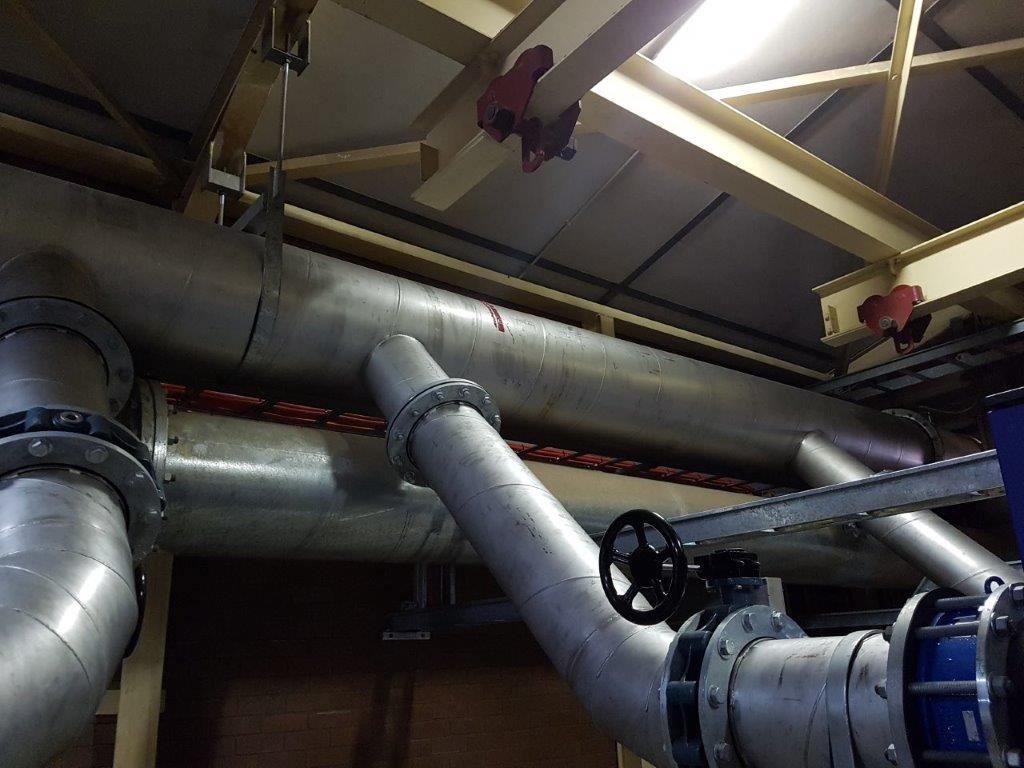

WARRNAMBOOL WTP – FILTER REFURBISHMENT

Design and Construction of Filter Renewals and Associated Works at Warrnambool Water Treatment Plant

The Warrnambool WTP Filter Refurbishment Project was a particularly challenging project to execute as strict adherence to schedule was required to ensure the WTP would be ready to ensure water security for the holiday season. On top of this requirement were the COVID working restrictions imposed upon us when COVID came into our world in 2020. A COVID Management Plan was created in line with government health advice and the work was able to continue and be completed, despite lockdowns, and slow downs, with confined space entry work often restricted, and worker proximity needing to be carefully managed. To the credit of the team no employee contracted COVID during their time on site, and security of supply to the city of Warrnambool was never compromised.

The project delivered:

- Refurbishment of All Four filter cells staged in separable portions

- Removal of filter media and launders,

- Removal of filter floor including cast-in filter nozzles and laterals,

- Sandblasting and repair of all internal filter surfaces,

- Epoxy coating of filter internal surfaces,

- Supply and installation of new laterals and filter nozzles,

- Supply and installation of new filter media,

- Reinstall and level launders.

- Testing and commissioning

- As-constructed drawings

- Defects liability

Value: $1.1M

Back to PROJECTS GALLERY

MERRIMU WFP – FLUORIDATION UPGRADE

The Merrimu WFP sodium fluoride system upgrade comprised the following elements:

• New fluoridation plant building, including a new electrical switchroom

• New sodium fluoride upflow saturator and day tank

• New sodium fluoride transfer pumps and dosing pumps

• New sodium fluoride dosing lines and injection point

• Modification to the existing treated water pipework to the Clear Water Storage tanks

• Modification to the existing service water supply pipework and new water softener

• New waste transfer pump and waste collection tank

• New safety showers (including eye wash stations) and service water hose reels

• New background (raw water) fluoride analyser

• New sample line to the existing treated water fluoride analyser

• New CWS feed flow meter

• Electrical and control system integration works

• New suction pipework to the Toolern Vale pumps

• New pipework to allow the 5ML Treated Water tank to be drained and diverted to Djerriwarrh Reservoir

• Modifications to the existing site road for chemical delivery and pedestrian access

• A new Allen Bradley MicroLogix 1400 PLC system. The new PLC will have an ethernet connection to the existing SCADA network switch located in PLC Panel within control room 2. The connection shall be fibre optic between buildings.

Value: $2.2M

Back to PROJECTS GALLERY

ELANORA STP REFURBISHMENT

The Elanora STP Digester A Upgrade delivered the following scope of works.

PART 1 – Anaerobic Digester Wall and floor refurbishment, mechanical equipment and Biogas Compressors replacement

PART 2 – Roof refurbishment, mechanical external and internal works,

PART 3 – Re – Routing and Replacement of Biogas Pipework

PART 4 – Digesters A, B, C Sludge Heaters Replacement

PART 5 – Electrical and Control Works

Value: $4.9M

Back to PROJECTS GALLERY

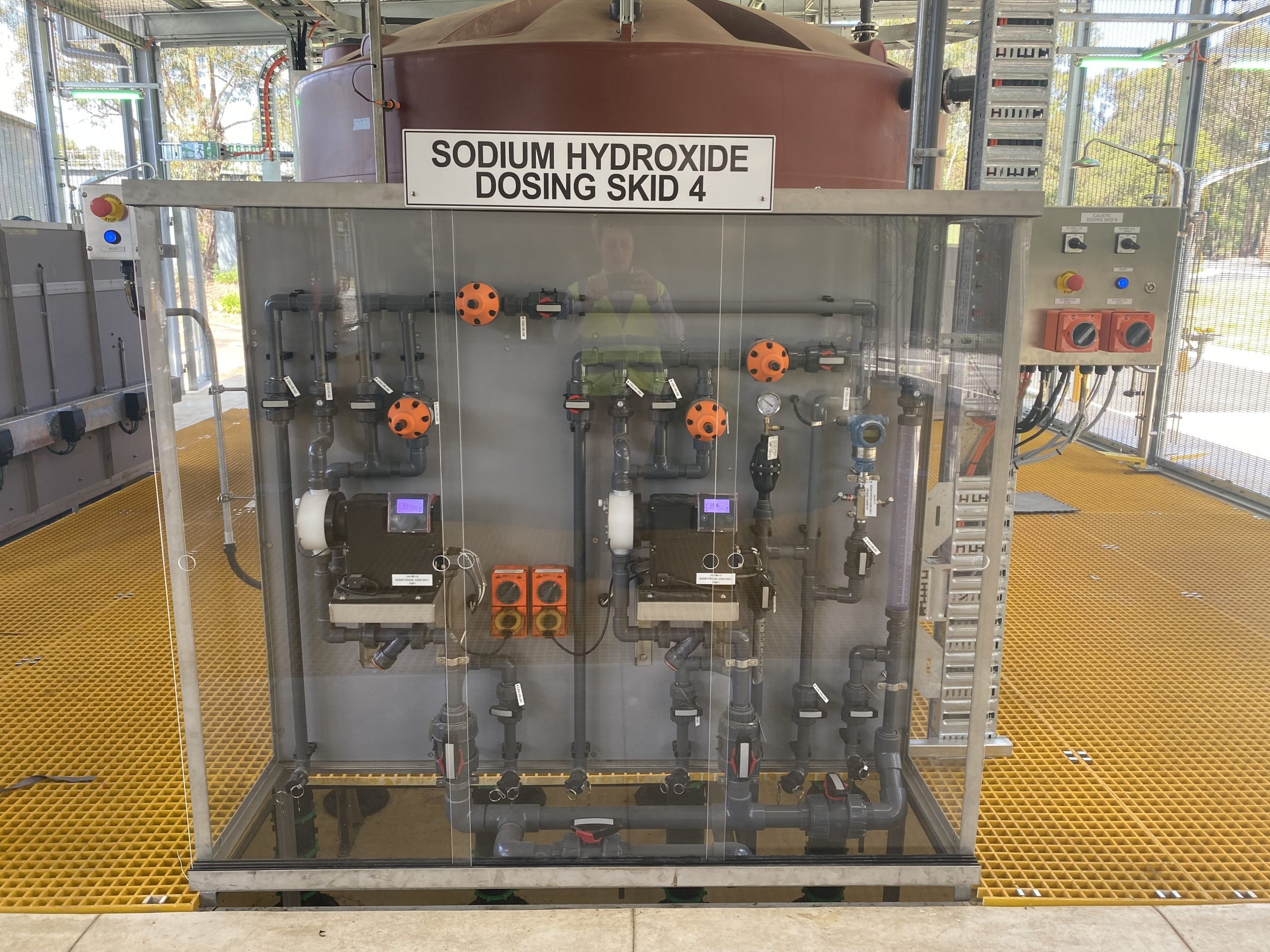

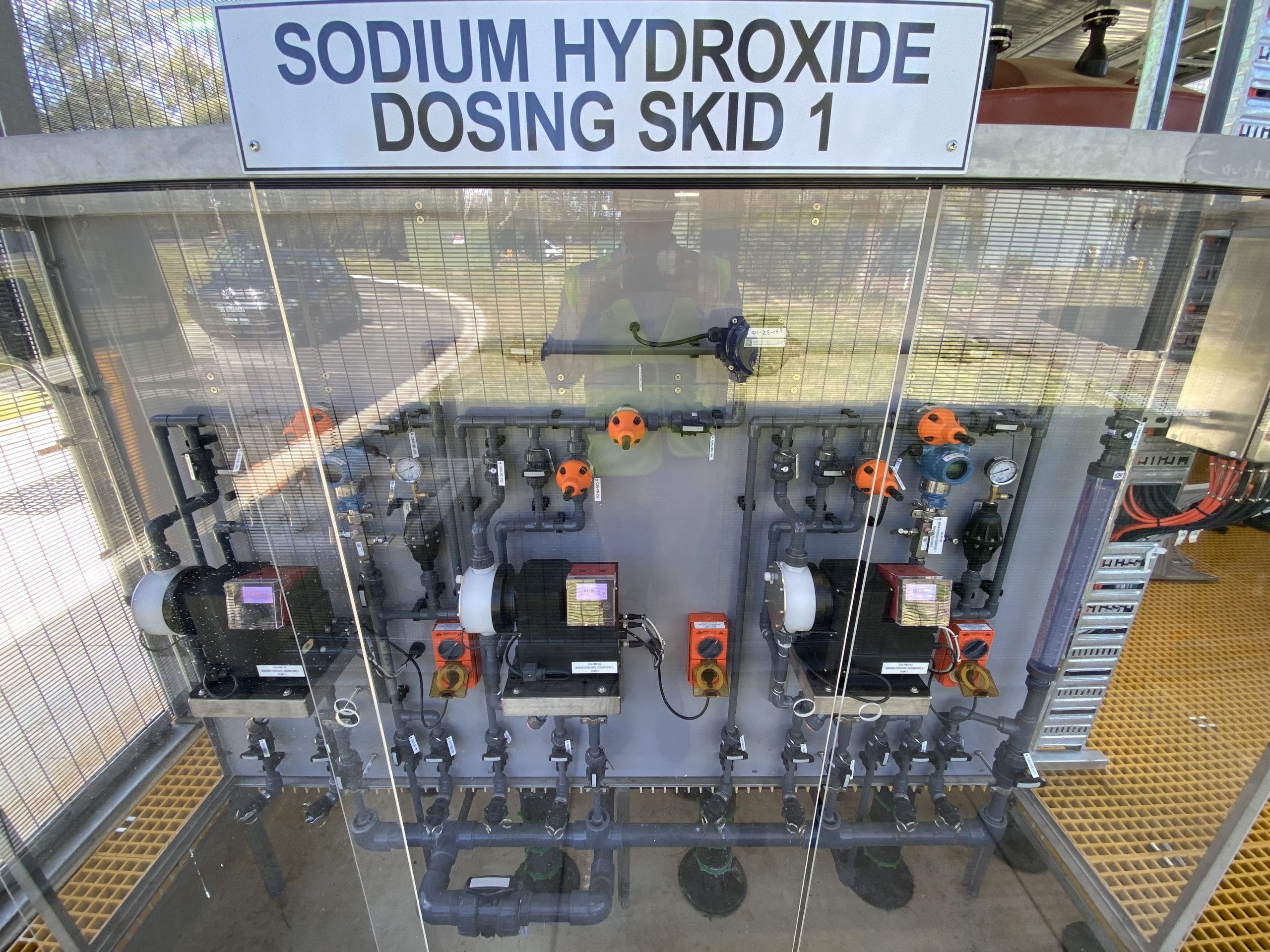

BRUSHY CREEK STP CHEMICAL DOSING UPGRADE

Yarra Valley Water required a new Brushy Creek STP Class B Chemical Dosing Facility.

The chemicals dosed at this facility are aluminium sulphate (alum) and sodium hydroxide (caustic). The upgrade included

– Construction of new chemical dosing facility (CDF) complete with

– Chemical storage bunds

– Chemical delivery area

– CDF enclosure

– Chemical storage tanks

– Dosing equipment

– Safety showers and eye wash stations

– Installation of new dose lines and dose points including above ground pipe support structure and cable ladders.

The dose points included:

– Alum downstream of the primary screens

– Alum upstream of the tertiary filters

– Caustic at the inlet of each of the Extended Aeration (EA) Tanks (6 off)

– Caustic downstream of the tertiary filters

– Installation of new drinking water offtake and piping to connect into existing drinking water pipelines around the treatment plant site.

Value $2.9M

Back to PROJECTS GALLERY

LAANECOORIE WTP UPGRADE

The Laanecoorie WTP has a nominal capacity of 3.8 ML/d and treats water from the Loddon River for supply of drinking water to the towns of Laanecoorie, Dunolly, Tarnagulla and

surrounding areas.

The upgrade works under this contract were brought about to address a series of issues in relation to the condition and performance of the WTP and enabled the plant to

meet the new proposed Health-Based Targets that were incorporated into the Australian Drinking Water Guidelines.

The broad scope of this upgrade included:

- New powdered activated carbon (PAC) contact tank including mixer, instruments, and walkway and modifications to clarifier inlet pipework to accommodate new PAC tank.

- New streaming current meter for dosed raw water.

- Filter media replacement:

- Including replacement of filter underdrains and air scour pipework.

- Filter washwater launder and outlet modifications

- Filter modifications:

- Instrumentation and pipework changes to enable fixed level flow split operation.

- Filter to waste pipework and valves.

- New UV disinfection plant housed in a new building.

- New chlorine contact tank including internal baffles.

- Relocation of chlorine and ammonia dose locations

- New treated water re-lift pumps.

- Replacement of filter backwash pump.

- Replacement of filter air scour blower.

- Removal of existing washwater tank, including

- Improvements to sludge lagoon,

- Replacement of supernatant return pump

- Electrical installation of all new equipment.

- Integration of all new equipment into existing plant PLC and SCADA.

- Testing and commissioning of the completed works.

Value $1.2M

Back to PROJECTS GALLERY

LANCE CREEK WTP PAC DOSING UPGRADE

The Lance Creek WTP treats water from the Lance Creek Reservoir, to supply drinking water to Wonthaggi, Cape Patterson, Inverloch, Korumburra, Poowong and Loch. The existing Lance Creek WTP can operate at a capacity of approximately 20.7ML/d, and is supplemented by the DP5 pipeline, which brings water from Cardinia Reservoir in Melbourne or the Victorian Desalination Plant into the Lance Creek CWS, where the two supplies are disinfected and blended to produce a consistent water quality to customers.

The water quality in Lance Creek Reservoir can deteriorate significantly due to algal blooms, reservoir draw down and turn over issues. The Lance Creek Reservoir raw water also has significant concentrations of organics, soluble manganese which, if not adequately controlled, can contribute to water quality non-compliance and customer complaints.

The water quality control measures at Lance Creek WTP are pre-treatment with powdered activated carbon (PAC) and potassium permanganate dosing, and pH correction dosing with caustic soda/hydrochloric acid as required to achieve stable alum coagulation and flocculation conditions for the DAFF process.

The Lance Creek PAC Dosing Upgrade project was developed to eliminate the OHS issues experienced and to improve the effectiveness of pre-treatment dosing generally.

The upgrade works provided:

- PAC dosing system package and building

- Materials handling and storage equipment

- Batching tank and mixer

- Dosing tank and mixer

- New dosing line and injection point

Value: $1.4M

Back to PROJECTS GALLERY

FLUORIDE DOSING UPGRADE – COLAC WTP

This fluoride dosing upgrade project was initiated to upgrade aging infrastructure at the Colac WTP, which had reached its design life and was becoming unsafe to use.

The project delivered:

- Simplification of the dosing system by removal of redundant valves, flush points and instrumentation

- Provision of two dosing panels to provide duty/standby capability. Each panel was provided with;

- Dosing pumps

- Pressure indicators

- Pulsation dampeners

- Pressure transmitters

- FSA flow meters

- Pressure sustaining valves

- Reduction of dosing pipeline diameter where appropriate to minimise the volume of chemical in the system during maintenance activities (e.g. flushing pipes)

- Addition to each FSA day tank of an ultrasonic level transmitter (already implemented at Colac WTP at the time of this review)

Value: $175K

Back to PROJECTS GALLERY

HEATHCOTE WTP UPGRADE

Heathcote WTP has a nominal inflow capacity of 5.5 ML/d and treats water from the Lake Eppalock or Caledonia Reservoir for the supply of drinking water to the towns of Heathcote and Tooboorac.

The Heathcote WTP Upgrade works under this contract addressed a series of issues in relation to performance including:

- Disinfection upgrades to meet the new proposed Health-Based Targets to be incorporated in the Australian Drinking Water Guidelines including:

- Power Supply and Main Switchboard Upgrade

- Ultraviolet (UV) disinfection.

- Modifications to the existing plant to achieve free chlorine contact time.

- New powdered activated carbon (PAC) system to remove taste and odour compounds from the water

- New wash water handling system to treat wash water and recover supernatant onsite, requiring geobags and laydown areas, thickeners, supernatant handling, and polymer dosing equipment.

- All testing and commissioning, O&M Manuals, WAE Drawings and Operator Training

For a Coliban Water commentary of the Heathcote WTP Upgrade Works during the process, please check out their Facebook post here.

Value: $3.4M

Back to PROJECTS GALLERY

WENO WWTP UPGRADE

The WENO WWTP Upgrade project saw LC Water work as a subcontractor to support CCB Envico to deliver this infrastructure upgrade.

The project demanded significant planning and logistics scheduling given the remote location of the works in Micronesia.

The WWTP plant rehabilitation demanded design, procurement, installation, and commissioning of:

- activated sludge clarifier mechanism, launders, access walkways, and scum rakes.

- New fine bubble diffuser system and blowers for the activated sludge unit.

- Treated effluent chemical dosing and disinfection system.

- 450 x Sulzer ABS Nopon disc diffuser membranes

- Distribution headers and pipework

- Blower manifolds, aeration header ring main, downcomers and connection to membranes

Value: $700K

Back to PROJECTS GALLERY

WEST WODONGA WWTP AERATION BLOWER UPGRADE

The Scope of Works included the design, supply, replacement, integration, testing, commissioning, and verification of high energy efficiency aeration blowers at the West Wodonga Waste Water Treatment Plant, with provision of performance guarantees.

The Scope also included the disposal of the existing six (6) aeration blowers to be replaced and all and any other equipment, materials and waste as a result of the SOW.

- 6 x Sulzer Turbocompressor Blowers

- 7200m3/h

- 150kW high efficiency

- Model No. HST 20-6000-1-150/U200

- Manifolds, valving and pipework

Value: $1.3M

Back to PROJECTS GALLERY

BRIGHT WWTP INLET WORKS UPGRADE

The previous inlet works screening system had reached the end of its design life, and the structural integrity of the concrete channel in which it operated had become seriously undermined through years of H2S attack of the concrete. This project was initiated to replace the Inlet Works Screen and Channel.

The works delivered the detailed design, supply, installation, and commissioning of;

- Rotary Drum Inlet screen rated to 100L/s, 3mm perforation, internally fed, and self-cleaning.

- Connecting Pipework

- Handrails and platforms

- General Civil Requirements and modifications/remediation of the existing concrete inlet works structure.

Value: $328K

Back to PROJECTS GALLERY

BENDIGO WRP ACH DOSING FACILITY UPGRADE

This ACH Storage and Dosing Facility Upgrade came about to improve the safety and reliability of ACH dosing to the plant.

The works delivered were comprised of:

-

- Detailed design and documentation.

- ACH dosing system including unloading bay, storage tank, dosing equipment, and ancillary works.

- Supply and installation of raw water monitoring (i.e. Turbidity and pH) instrumentation

- Potable water booster pump and pipework to increase water pressure, a hose down point, and a hose reel.

- Electrical installation of all new equipment.

- Integration of all new equipment into the existing plant PLC and SCADA.

- Testing and commissioning

- As-constructed documentation (drawings, updated asset data register, and updating relevant sections of the existing tertiary filter O&M manuals).

Value: $549K

Back to PROJECTS GALLERY

MOBILE PAC DOSING TRAILER

This innovative project was conceived to overcome the challenge of the impacts of algal toxins and taste and odour at a number of water treatment plants where the raw water may become impacted only seasonally. As the installation of on-site PAC dosing systems at each of plant of concern would have been expensive, not to mention not required at all throughout most of the year, it was thought that a MOBILE PAC Plant that could be transported to a troubled plant and used only during times of need would solve the problem.

The project delivered the following features:

- Design and fabrication of PAC preparation and dosing system with all necessary equipment mounted on a roadworthy trailer

- Venturi type loading system (to suck dry PAC powder out of 15-20 kg bags) with high-pressure service water connection, to wet PAC on transfer to a batching tank

- Batching tank fitted with motorised mixer

- Peristaltic (hose) PAC dosing pumps (2 no.) and associated pipework including flushing points

- Service water and hose connections to the Water Treatment Plant service water connection point for batching, flushing, and dosing carrier water, with service water booster pump on the trailer for the operation of the venturi unloading system

- Flushing system designed to dose into a nominated range of flows to ensure the system can be moved between 10 identified sites

- Weatherproof electrical panel with HMI touch screen

- Provision for both Flow Paced and Manual dosing control

- 4G modem to communicate with the client’s central SCADA system

- Basic operational signals provided by the WTP via a standardised socket connection

- Each site fitted with identical connections for service water, control signals and power to permit simple connection from trailer to WTP’s connection points.

- Factory Acceptance Testing of the completed mobile PAC dosing system at the Contractor’s workshop

- Pre-commissioning and Commissioning

- 5-day duration Proof of Performance Testing

- Training of operational staff in the operation and maintenance of the mobile PAC dosing trailer

Value: $258K

Back to PROJECTS GALLERY

COHUNA FLUORIDE DOSING UPGRADE

The Cohuna Fluoride Dosing Upgrade delivered:

- Design and construct a new building to house the new infrastructure.

- Replace the existing DN300 filtered water flowmeter

- Demolition of an existing Sulfuric Acid dosing system

- Testing commissioning and proof of performance testing

- As constructed documentation (manuals and drawings)

- Operator training.

- Integration of the new Fluoride plant into the main WTP PLC including SCADA and HMI screens.

To view the Coliban Water Youtube of the opening of the plant following the upgrade, click here.

Value: $620K

Back to PROJECTS GALLERY

MELTON RWP WtE FACILITY

The works completed under this project included all design, supply, construction, installation, testing, and commissioning of associated works to construct the new WtE system at Melton RWP including:

- One (1) waste receiving station with hot water wash water system

- One (1) screenings bin

- Transfer pump to waste storage tanks

- Repurpose existing 2 x 16 m3 tanks into waste storage tanks complete with insulation and mixing

- Use existing sludge recirculation pumps to transfer warm sludge from the Digester 2 to the waste storage tanks using existing scum pipeline

- Transfer pump(s) to the anaerobic digestion facilities using existing scum pipeline via digester mixing system

- Repurpose existing odour control for waste receiving station and both waste storage tanks

- Reuse existing electrical switchboard

- Hot water flushing for waste receiving facility

- Provide additional pipeline connecting organic waste transfer pump station to the existing scum pipeline near primary sedimentation tanks 1

- Provide sufficient rodding points and drain points to clean the pipework

- PLC and SCADA programming for automation of receival system and of the mixing, storage and transfer of warm sludge to the waste storage tanks and waste to the Digester 2

- Bunded equipment area complete with a sump and drain system the ability to drain to the existing site drainage system and to the existing filtrate pump station.

Value: $1.1M

Back to PROJECTS GALLERY

JINDABYNE WTPs FLUORIDE DOSING UPGRADES

Upgrade and refurbishment of three fluoride dosing facilities in the Snowy Mountains town of Jindabyne, NSW.

The project delivered:

- the removal and demolition of current dosing room contents,

- refurbishment of plant room completed with consideration for dust minimisation,

- D&C of fluoride storage and dosing systems,

- NaF dust suppression delivery and saturation systems,

- double insulated injection lines,

- injection quill installations and underground pipework.

Value: $1.1M

Back to PROJECTS GALLERY

MELTON RECYCLED WATER TREATMENT PLANT

LC Water supported head contractor CCB Envico in the design and construction of the new anaerobic digester and biogas handling facilities.

LC Water was responsible for the D&C of the biodome, biogas flare system, chemical dosing facilities, all mechanical installation work, installation of all heating, (package boiler), heat exchange and mixing systems, and commissioning of all of the above.

This project provided LC Water with direct and recent experience in all aspects of anaerobic digestion and biogas generation, biogas handling, flaring, polishing and storage, electricity cogeneration.

The delivery included:

- A Landia pumped/gas mixing system to negate the need for hazardous area rated gas mixing system.

- A double membrane gas holder for biogas storage

- An enclosed flare which permitted use on days of Total Fire Ban

Value: $2.8M

Back to PROJECTS GALLERY

KILMORE WMF UPGRADE

The Kilmore WMF Upgrade was driven by a need to increase the nitrification capability of the aerated lagoon treatment system in Kilmore.

To achieve this, a key aspect of the project was to deliver the installation of new mechanical blowers, blower building, manifolds, headers and pipework to support a proprietary biomesh diffused aeration system in the first stage storage lagoon.

Also required were replacement of Inlet Works, New ALUM chemical dosing building, storage, delivery bund and safe transfer system, dosing systems and double insulated underground piping to dosing points throughout plant.

Value: $4.8M

Back to PROJECTS GALLERY

CORRYONG WTP

The Corryong Water Treatment Plant is a 3.2 ML/d dual train Dissolved Air Flotation and Filtration (DAFF) Water Treatment Plant which treats water for supply to Corryong in North East Victoria.

Laurie Curran Water was the principal contractor for this project, which incorporated caustic soda, alum, polyelectrolyte and gaseous chlorine dosing processes into the design to ensure the treated water meets the requirements of the Australian Drinking Water Guidelines (ADWG).

Value: $4.3M

Back to PROJECTS GALLERY

KING ISLAND WTP

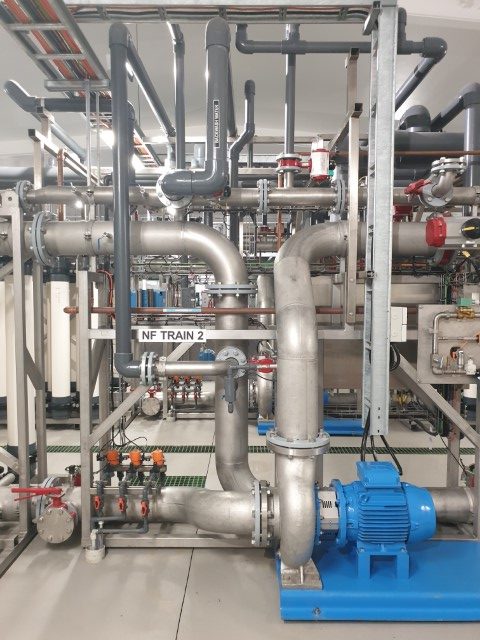

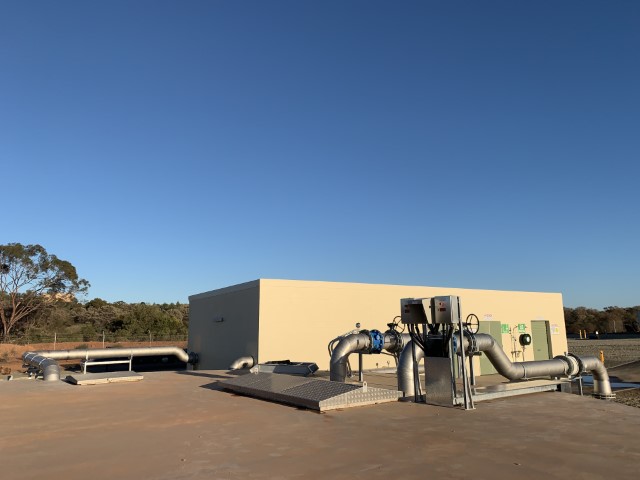

- 1 MLD DAF+ Nanofiltration Plant

- Process Train: pH adjust, COAG + FLOC >> DAF>> Nanofiltration Plant >> GAC >> UV Disinfection >> Chlorination, Fluoridation >> Reticulation

- Project also demanded full scale building to house the plant, all chemical dosing, NF CIP and backwash systems.

- Electrical Design and Installation, PLC and SCADA Automation completed by WATTERS under LC Water’s integrated management system framework of project governance.

- Please follow the link below to take a virtual tour of the plant, courtesy of TasWater: https://tourview.com.au/taswater/ki-wtp.html?html5=prefer

Value: $10.3M

Back to PROJECTS GALLERY

COBAR WTP

The Cobar WTP is an 8 MLD plant designed and constructed to cope with high turbidity, high colour water pumped 130km to Cobar water storages from the Nyngan Weir Pool, which in turn is transferred via a 73km open channel from the Macquarie River.

The key process units of the plant are comprised of dual train lamella clarifiers – LCW bespoke custom designed and fabricated to suit high turbidity expectations in raw water quality (3-400NTU; 10-1000 AC HU expected), followed by a Four train Dissolved Air Flotation and Filtration (DAFF) system housed in concrete water retaining structure.

These processes are supported by a range of chemical dosing systems to support treatment of colour and dissolved organics (PAC dosing, KMnO4 dosing) pH correction (soda ash dosing), coagulation and flocculation (ACH and polymer dosing), disinfection (UV + Gaseous Chlorine dosing), and facility for future dosing of fluoride. LC Water also designed and constructed the sludge lagoon systems to handle the DAFF waste stream.

The ELEC/PLC/SCADA work was subcontracted by LCWater to EDC, a team with whom we have worked for many years, and whose work was project managed by LCWater throughout. LC Water also fully commissioned the plant ourselves, developing all management plans, functional descriptions, and ITPs ourselves.

The works were a success because the plant operates as specified, and is currently treating the incoming water defined above to ADWG specifications.

For a link to an account of the opening ceremony, click here.

Value: $9.5M

Back to PROJECTS GALLERY

BOURKE WTP

LC Water won the contract to design and construct a 3.5MLD Water Treatment Plant for the Bourke Shire Council in August 2019. Bourke is a remote western NSW township which was struggling with water quality issues due to drought and aged infrastructure.

The scope of works delivered a process train comprised of: KMnO4 and PAC treatment, Chemical dosing (coag, floc, soda ash) flocculation vessels, signficant concrete water retaining structures for clarification and filtration, disinfection (UV + Chlorine), Fluoridation, and pH correction. Buildings to house lab and other equipment along with roadworks were also delivered.

Value: $10.1M

Back to PROJECTS GALLERY

CROOKWELL WTP

The Crookwell WTP is a 4 MLD plant designed and constructed to cope with moderate turbidity and colour and algae contaminated water drawn from Crookwell Dam, which is fed from Kentgrove Creek. Bore Water also supplements this supply, meaning iron and manganese also posed challenges. 2-22 NTU; 0-47 TC HU were expected.

This WTP is a DAFF system comprised of:

- A potassium permanganate reaction tank which is also be used as a Balance Tank located at the new WTP site to receive raw water from the dam and/or the bores

- A PAC Dosing System upstream of lime, CO2 and KMnO4

- Lime and carbon dioxide dosing systems

- Coagulant feeding system

- An inline static mixer to mix the lime and the coagulant prior to the flocculation tank

- A flocculation tank to form good flocs size

- Dual DAFF trains ( 2 x 2MLD) to remove flocs

- Alkali post dosage if necessary

- Fluoridation and chlorination chemical dosing systems.

- A Clearwater Balance Tank and Clearwater pump station to transfer the treated water from the new WTP to the town using the existing clear water distribution and storage system

- A filter backwash pipeline from the clear water rising main to the new filters. Filter backwash water and service water are drawn from the clear water rising main

- A wastewater discharge pipeline from new water treatment plant to the existing sludge lagoons.

The ELEC/PLC/SCADA work was subcontracted by LCWater to a team with whom we have worked for many years, and whose work was project managed by LCWater throughout. LC Water also fully commissioned the plant developing all management plans, functional descriptions and ITPs in-house.

Value: $5.3M

Back to PROJECTS GALLERY

WALLAN WWTP

The works at the upgraded WWTP includes the intermittently decanted extended aeration (IDEA) process along with the Tertiary Filters for recycling the water suitable for further Class A treatment. An IDEA based process provides both functions of a traditional activated sludge treatment process with aeration and settling within the same IDEA tank.

LCW provided all the mechanical equipment including the decanters and chemical dosing systems for the contract, designed and constructed the Tertiary Filter system and managed the commissioning process.

Value: $3.5 M

Back to PROJECTS GALLERY

FREEBURGH WTP

The Freeburgh Water Treatment Plant is a 5.0 ML/d dual train Dissolved Air Flotation and Filtration (DAFF) Water Treatment Plant that treats water for supply to Bright in North East Victoria.

Laurie Curran Water was the principal contractor for this project. The treatment plant incorporated PAC, alum, caustic soda, polyelectrolyte and gaseous chloring dosing processes into the design to ensure the treated water meets the requirements of the Australian Drinking Water Guidelines (ADWG).

Given that the location was particularly prone to bushfires, the architect-designed building was fitted with a bushfire protection deluge system, configured to envelop the plant in water spray to protect it from ember attack.

Value: $5.6 M

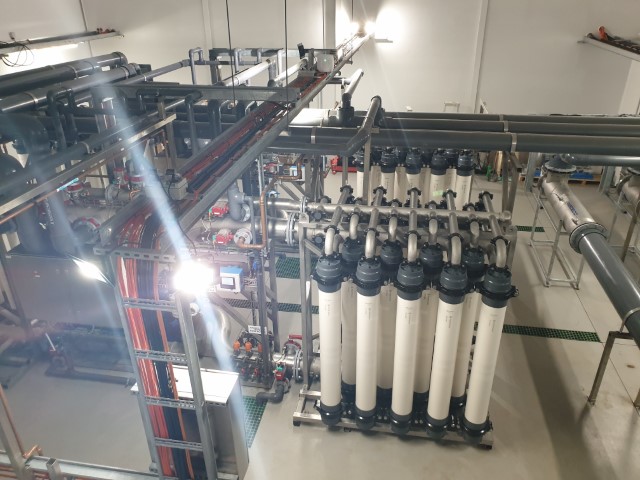

LADY BARRON, WHITEMARK AND MOLE CREEK WTPs

This project involves the design and construction of three water treatment plants ranging in capacity from 0.45Mld to 0.6Mld.

Laurie Curran Water is the principal contractor for this project, which incorporates various water treatment processes and technologies including filtration, ultrafiltration, and nanofiltration to ensure the treated water meets the requirements of the Australian Drinking Water Guidelines (ADWG).

Value: $10M

NUMURKAH WTP

The Numurkah Water Treatment Plant is a 10ML/d Dissolved Air Flotation Filtration (DAFF) Water Treatment Plant which treats water for supply to Numurkah in Victoria.

Laurie Curran Water was the principal contractor for this project, which incorporated PAC dosing, pH correction dosing systems, coagulation and flocculation (including alum, and poly dosing), disinfection and dissolved air flotation and filtration (DAFF) into the design to ensure the treated water meets the requirements of the Australian Drinking Water Guidelines (ADWG).

Value: $6.3 M

LEONGATHA WWTP

This project involved the upgrade of two anaerobic digesters at the Leongatha WWTP. The digesters and associated pipework are being upgraded along with a new heating water and sludge mixing system.

Value: $2.2 M

GUNNING WTP

The Gunning Water Treatment Plant is a 1.0 ML/d Dissolved Air Flotation and Filtration (DAFF) Water Treatment Plant which will eventually treat water for supply to Gunning in the Southern Tablelands of NSW.

Laurie Curran Water was the principal contractor for this project, which incorporated caustic soda, ACH,gaseous chlorine and fluoride dosing processes into the design to ensure the treated water meets the requirements of the Australian Drinking Water Guidelines (ADWG).

Value: $3.7 M

MARYSVILLE WTP

The Marysville Water Treatment Plant is a 2ML/d Membrane Filtration Water Treatment Plant that treats water for supply to the Marysville township in Victoria.

Laurie Curran Water was the principal contractor for this project, which incorporated pH correction dosing systems, coagulation, and flocculation (including ACH dosing) disinfection, and membrane filtration (ultrafiltration) into the design to ensure the treated water meets the requirements of the Australian Water Drinking Guidelines (ADWG).

The site presented two key challenges which needed to be addressed. Given that this region was especially prone to bushfires, the building and tank structures needed to be built to withstand such an event. Secondly, as the location for the plant was near the shoulder of the existing raw water storage lagoon, a geotechnical investigation revealed the location had not been sufficiently compacted. This discovery led to the inclusion of screw piling to ensure the integrity of the building and tank foundations.

Value: $4.3 M

GUNBOWER WTP

The Gunbower Water Treatment Plant is a 0.65 ML/d capacity Water Treatment Plant which will provide treated water for the township of Gunbower in Northern Victoria. The customers in the area consist of residential, light industrial and semi-rural. The plant utilises the Taylors Creek raw water source.

The Gunbower WTP uses ion exchange through a Miex Unit, clarification, membrane filtration through a Pall Membrane Unit and Granular Activated Carbon (GAC) filtration to ensure the treated water meets the requirements of the Australian Drinking Water Guidelines (ADWG).

SHOALHAVEN HEADS WWTP

The upgrade works at Shoalhaven Heads WWTP replaced the existing activated sludge wastewater treatment process using Pasveer Channels with an intermittently decanted extended aeration (IDEA) process. An IDEA based process provides both functions of a traditional activated sludge treatment process with aeration and settling within the same IDEA tank.

All works were carried out while the plant was live.

MYRTLEFORD WTP

The Myrtleford Water Treatment Plant is a 6 ML/d Dissolved Air Flotation Filtration (DAFF) Water Treatment Plant which treats water for supply to Myrtleford in North East Victoria.

Laurie Curran Water was the principal contractor for this project, which incorporated lime, CO2 and aluminium chlorohydrate dosing processes into the design to ensure the treated water meets the requirements of the Australian Drinking Water Guidelines (ADWG).

BARWON WATER FLUORIDATION PROJECT

This project involved the construction of three fluoridation facilities at Wurdee Boluc WTP, Colac WTP and Moorabool WTP. To deliver the project CCB Envico partnered with Laurie Curran Water who had the role as the process designer and mechanical installation contractor.

All design was carried out in accordance with the requirements of the Australian Drinking Water Guidelines (ADWG).

WOODGLEN WTP

This project required the design and construction of a 20 MLD DAFF water treatment plant on a greenfield site in East Gippsland, Victoria.

LC Water supported head contractor, CCB Envico, as process design engineers and mechanical installers.

Key elements of the process train included:

- Raw Water Blending Chambers

- PAC, and other Chemical Storage and Dosing Systems

- DAFF

- Chlorine Disinfection

- Wastewater Handling – Sludge Holding Tank, Lamella Type Sludge Thickener

- Mechanical Dewatering (centrifuge) supported by polyectrolyte dosing

- Clear Water Storage

Value $2.7M

GOULBURN VALLEY WATER FLUORIDATION PROJECT

This project involved the construction of three fluoridation facilities at Cobram WTP, Kyabram WTP and Seymour WTP. To deliver the project, CCB Envico partnered with Laurie Curran Water who had the role as the process designer and mechanical installation contractor.

All design was carried out in accordance with the requirements of the Australian Drinking Water Guidelines (ADWG).

SMALL TOWNS WTP PROJECT

The Small Towns WTP Project involved the design and full construction of 4 Dissolved Air Flotation Filtration (DAFF) Plants at Bemm River, Cann River, Buchan and Swifts Creek in East Gippsland, Victoria, ranging from 0.3 Mld to 0.8 Mld in capacity.

The plants each treat highly coloured river water of low to mild turbidity to meet the requirements of the Australian Drinking Water Guidelines (ADWG).

MELBOURNE CITY LINK RECYCLED WATER PLANT

This project involved the design and construction of a groundwater treatment and recycling facility for CityLink Melbourne Ltd, which treats groundwater taken from Melbourne’s CityLink tunnel system to remove alkalinity and recycles the treated water by injecting it back into the groundwater systems in Richmond and South Melbourne.

Laurie Curran Water now also maintains and operates the CityLink groundwater treatment system which includes full operation and maintenance of the treatment plant in Swan St, Richmond.

The media release by Melbourne Water details the design considerations for the CityLink groundwater treatment system.

-

BROGO WTP

BROGO WTP

-

TERANG WTP FLUORIDE DOSING PLANT

TERANG WTP FLUORIDE DOSING PLANT

-

DROUIN WASTEWATER TREATMENT PLANT

DROUIN WASTEWATER TREATMENT PLANT

-

LILYDALE STP – FILTER REFURBISHMENT

LILYDALE STP – FILTER REFURBISHMENT

-

Eildon Wastewater Management Facility Tertiary Upgrade

Eildon Wastewater Management Facility Tertiary Upgrade

-

WARRNAMBOOL WTP – FILTER REFURBISHMENT

WARRNAMBOOL WTP – FILTER REFURBISHMENT

-

MERRIMU WFP – FLUORIDATION UPGRADE

MERRIMU WFP – FLUORIDATION UPGRADE

-

ELANORA STP REFURBISHMENT

ELANORA STP REFURBISHMENT

-

BRUSHY CREEK STP CHEMICAL DOSING UPGRADE

BRUSHY CREEK STP CHEMICAL DOSING UPGRADE

-

LAANECOORIE WTP UPGRADE

LAANECOORIE WTP UPGRADE

-

LANCE CREEK WTP PAC DOSING UPGRADE

LANCE CREEK WTP PAC DOSING UPGRADE

-

FLUORIDE DOSING UPGRADE – COLAC WTP

FLUORIDE DOSING UPGRADE – COLAC WTP

-

HEATHCOTE WTP UPGRADE

HEATHCOTE WTP UPGRADE

-

WENO WWTP UPGRADE

WENO WWTP UPGRADE

-

WEST WODONGA WWTP AERATION BLOWER UPGRADE

WEST WODONGA WWTP AERATION BLOWER UPGRADE

-

BRIGHT WWTP INLET WORKS UPGRADE

BRIGHT WWTP INLET WORKS UPGRADE

-

BENDIGO WRP ACH DOSING FACILITY UPGRADE

BENDIGO WRP ACH DOSING FACILITY UPGRADE

-

MOBILE PAC DOSING TRAILER

MOBILE PAC DOSING TRAILER

-

COHUNA FLUORIDE DOSING UPGRADE

COHUNA FLUORIDE DOSING UPGRADE

-

MELTON RWP WtE FACILITY

MELTON RWP WtE FACILITY

-

JINDABYNE WTPs FLUORIDE DOSING UPGRADES

JINDABYNE WTPs FLUORIDE DOSING UPGRADES

-

MELTON RECYCLED WATER TREATMENT PLANT

MELTON RECYCLED WATER TREATMENT PLANT

-

KILMORE WMF UPGRADE

KILMORE WMF UPGRADE

-

CORRYONG WTP

CORRYONG WTP

-

KING ISLAND WTP

KING ISLAND WTP

-

COBAR WTP

COBAR WTP

-

BOURKE WTP

BOURKE WTP

-

CROOKWELL WTP

CROOKWELL WTP

-

WALLAN WWTP

WALLAN WWTP

-

FREEBURGH WTP

FREEBURGH WTP

-

LADY BARRON, WHITEMARK AND MOLE CREEK WTPs

LADY BARRON, WHITEMARK AND MOLE CREEK WTPs

-

NUMURKAH WTP

NUMURKAH WTP

-

LEONGATHA WWTP

LEONGATHA WWTP

-

GUNNING WTP

GUNNING WTP

-

MARYSVILLE WTP

MARYSVILLE WTP

-

GUNBOWER WTP

GUNBOWER WTP

-

SHOALHAVEN HEADS WWTP

SHOALHAVEN HEADS WWTP

-

MYRTLEFORD WTP

MYRTLEFORD WTP

-

BARWON WATER FLUORIDATION PROJECT

BARWON WATER FLUORIDATION PROJECT

-

WOODGLEN WTP

WOODGLEN WTP

-

GOULBURN VALLEY WATER FLUORIDATION PROJECT

GOULBURN VALLEY WATER FLUORIDATION PROJECT

-

SMALL TOWNS WTP PROJECT

SMALL TOWNS WTP PROJECT

-

MELBOURNE CITY LINK RECYCLED WATER PLANT

MELBOURNE CITY LINK RECYCLED WATER PLANT